AURRELIA – Optimization of wet processing techniques for the recovery of recyclable fractions from spent lithium-ion batteries

The aim of the AURRELIA research project is to optimize the recycling process of post-consumer lithium-ion batteries (LIBs) by developing suitable processes along the process chain from mechanical to hydrometallurgical processing. The aim is to make the largest possible proportion of a LIB accessible for recycling.

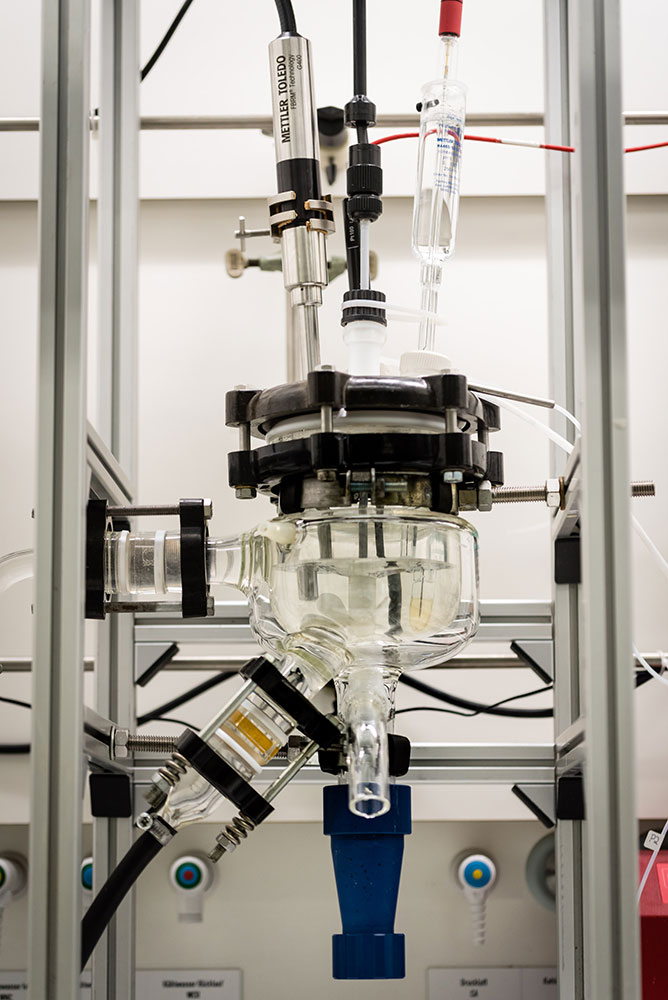

In terms of a zero-waste process, the project aims at high yields and purities of the obtained products. A central part of the project is the material-specific and economical processing of the LIBs, for which suitable shredding and processing methods are examined. Using an optimized shredding technology, the LIBs are comminuted in a wet environment and then separated into solid and liquid phases. This allows for material-specific treatment of the material streams and, thus, a comprehensive recovery of the LIB components is possible. In particular, the focus is on avoiding lithium losses. The process starts with a shredding step in aqueous environment, which eliminates the need to manually dismantle the batteries. This is followed by a product-oriented separation in order to obtain solids and liquid phases as separate fractions. The constituents of the electrolyte and the conducting salt brought into solution are to be selectively separated from the aqueous phase and recovered by means of membrane technologies and precipitation. In the hydrometallurgical processing steps, the wet-chemical process route is to be optimized with regard to the achievable product yield and purity of the metal salts. For the first time, particularly environmentally friendly and biodegradable leaching agents are used. With the results obtained, a concept for optimal LIB recycling is then developed, which is to be tested on pilot scale. The project aims to make a significant contribution to the focus of future LIB recycling processes.

Contact

RWTH Aachen University – Aachener Verfahrenstechnik – Chair for Fluid Process Engineering (AVT.FVT)

Prof. Dr.-Ing. Andreas Jupke

Stephan Musholt

Forckenbeckstraße 51, 52074 Aachen

Duration of project

01.01.2021 – 31.12.2023

Involved partners